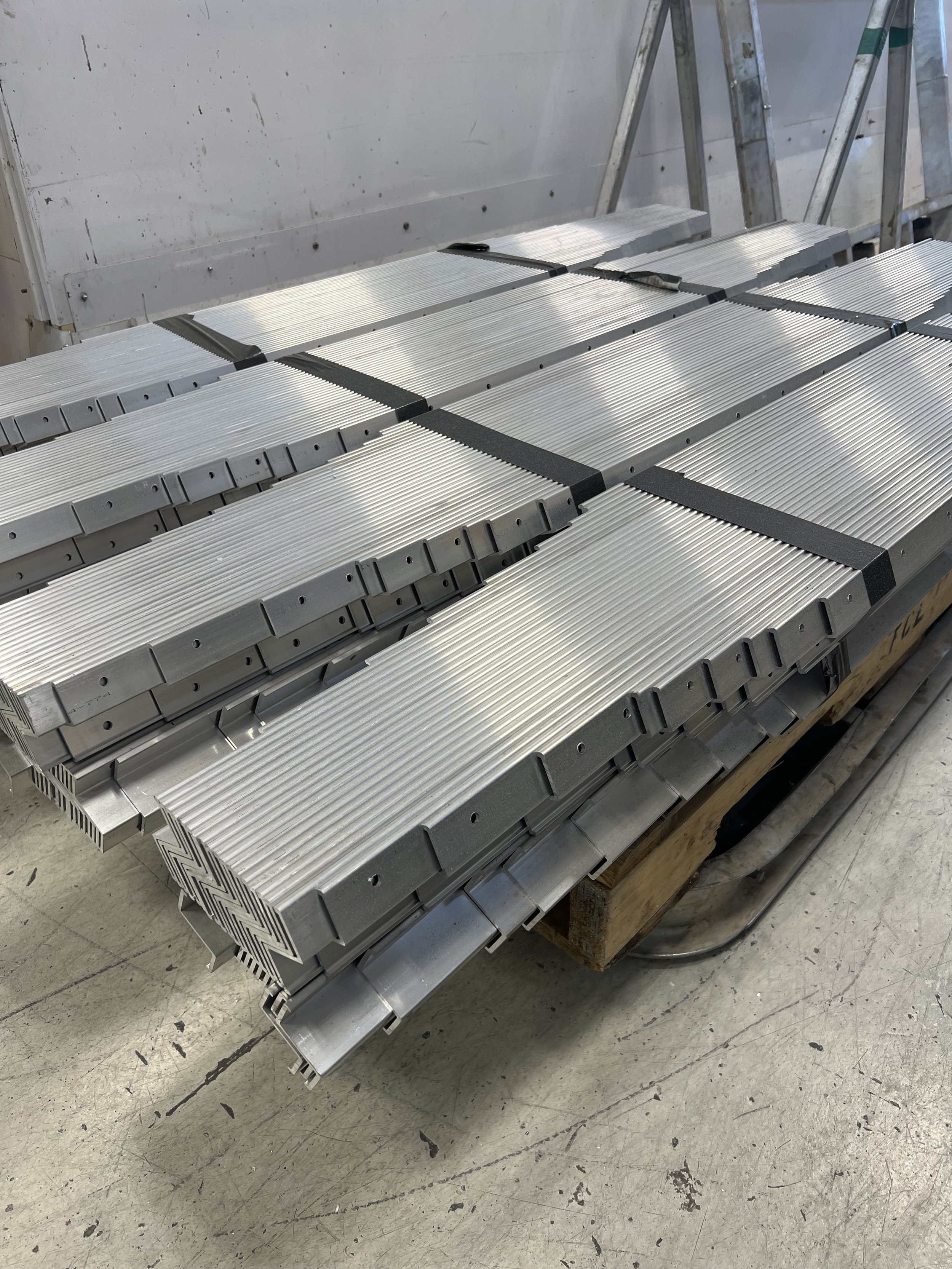

Extrusion Processing

At Lean Machine we are able to work with a wide variety of custom extrusions using our CNC 5-Axis Gantry Mill. We can custom make jaws and devices to allow for efficient and effective milling of parts, while maintaining a consistent quality for milling a variety of hole sizes on many different shapes and sizes of extrusions. Some of the parts we produce on the 5-Axis can be up to 26 ft. The 5-Axis allows for easy and quick set ups for multiple sides of parts, resulting in minimal setup time and reduced costs to our customers.

CNC 5-Axis Milling

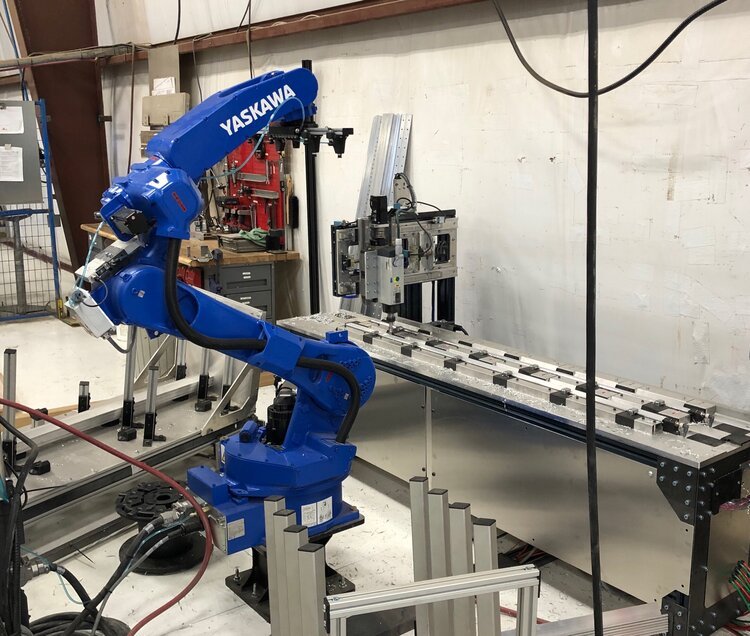

Robotic Extrusion

We also produce many high volume, repeatable parts that use robotics to automate the production process. Utilizing a robotic arm, we are able to set up trays of parts that the robot will collect and place on the bed for producing. Once the milling process is completed, the robot will collect the part and place it in the completed part tray. Using robotics for these parts can ensure consistent quality while eliminating waste of having to set up each individual part.